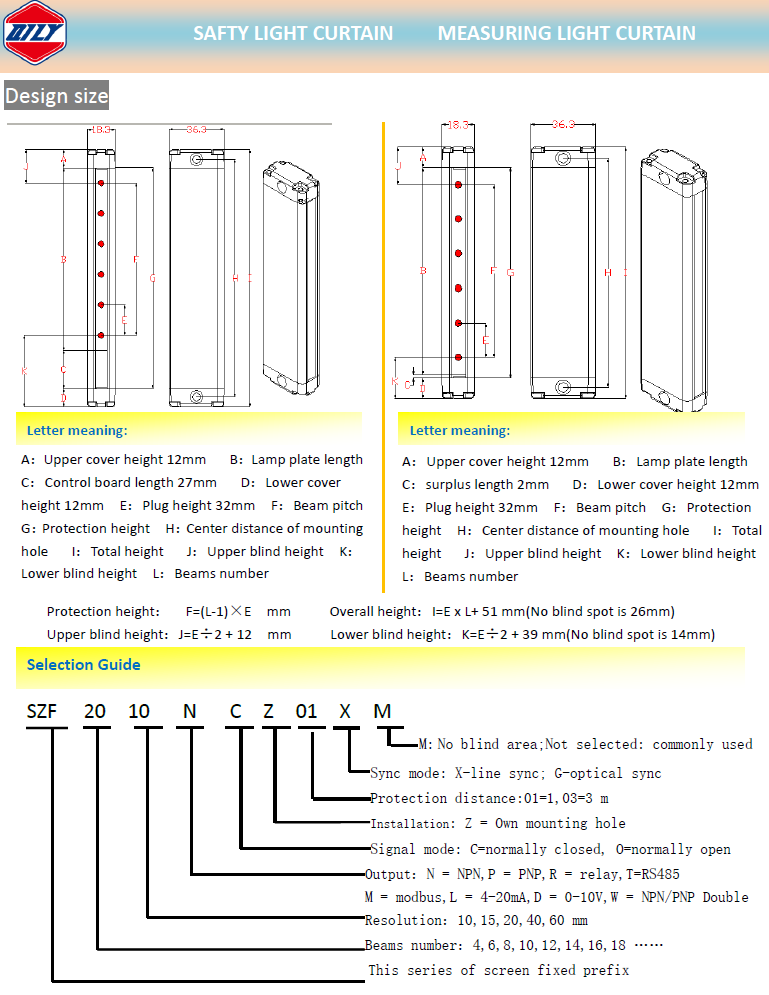

SZF series Ultra-thin safety light curtain Safety grating, side light, cross-sectional area: 18*35 mm

Overview

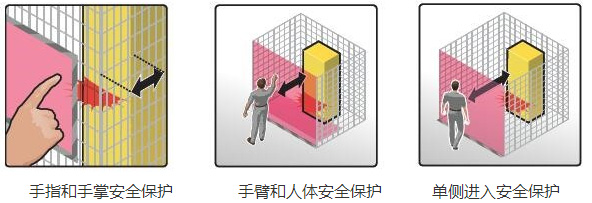

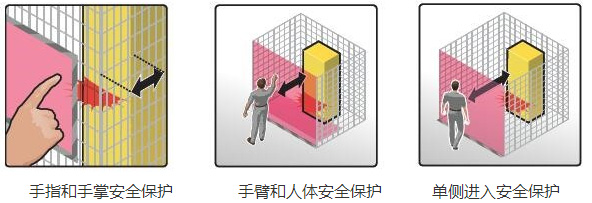

The SZF series of safety light curtains are extremely cost-effective and are the perfect solution for hazardous point protection and one-sided access protection, helping users to easily achieve safety protection from start to finish.

The SZF side light-emitting safety light curtain is a model of the core concept of “protecting the pure safety of machines and operators”, which can precisely protect the safety of machines and operators. Each of Keli's product lines is designed for specific applications and takes into account environmental factors.

The combination of safety and efficiency - the most practical

In all industries, the cost-effective SZF series of safety light curtains guarantee the safety of personnel and machines and systems (such as those used in processing machines of various sizes).

Typical application areas include:

■ Machine tool industry

■ Press industry

■ Automotive industry

■ Fixture equipment

■ Handling and storage system

■ Welding equipment

■ Consumer goods and packaging industry

■ Regional protection

■ Test equipment

■ Food manufacturing

■ Electronic equipment industry

■ Thermoforming machine industry

■ Medical equipment industry

■ Robot manufacturing industry

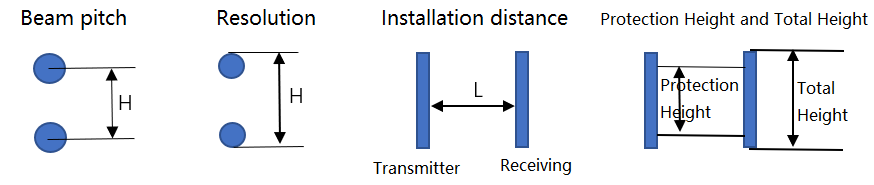

SZF ultra-thin safety light curtain safety grating – technical specification overview

■ Level 2 security protection

■ No blind zone / blind zone Optional

■ Resolution: 10/15/20/30/40/60 mm

■ Protection zone height: 60 mm to 2000 mm

■ Automatic range measurement of protection zone width up to 5m

■ Ambient operating temperature: –30°C to +65°C

■ Enclosure protection rating: IP 65

■ M12 aviation plug

SZF series basic safety light curtains are widely used in various safety applications

For extremely limited space: continuous protection zone

For extremely limited space: continuous protection zone

The SZF series of safety light curtains form a high-resolution continuous protection zone that covers the entire enclosure up to the end of the enclosure, minimizing the safety distance required for machine integration. In addition, the SZF series safety light curtains have a protection area of up to 3m. As a result, the product allows distances above and below the safe area to be much smaller than existing safety standards. The SZF series safety light curtain also reduces the safety distance between the operator and the danger point, effectively improving production efficiency.

Sturdy casing: SZF series safety light curtain adopts high-strength aluminum profile as the outer casing to ensure the safety light curtain is resistant to bending and impact.

Power-on: No security is required without any setup, and work and troubleshooting are fast.

Quick commissioning with LED indicators: The SZF series of safety light curtains can be used to perform all basic functions without pre-configuration and without the need for software. In addition, some models are equipped with integrated LED indicators and diagnostics, which effectively reduces commissioning time.

Plug-and-play maintenance and replacement: SZF series safety light curtains can be quickly maintained without configuration or wiring. All products feature an exquisite bracket design and standardized M12-4 pin plug technology, simplifying the replacement process for each device. In addition, bright LEDs continuously provide status information for all processes.

The SZF series of safety light curtains are designed with a sturdy and clean shape to ensure that the product meets the functional requirements. The SZF series of safety light curtains are specifically designed for operation and protection applications. They can be started immediately after power-on, without a lot of configuration work, and the detection range can be precisely adjusted according to the application needs. In addition, the safety light curtain has the following features:

? Integrated alignment LEDs for fast and accurate positioning of the transmitter and receiver in optimal relative position;

? Equipped with red/green LED indicators to clearly show the current working status of the safety light curtain.

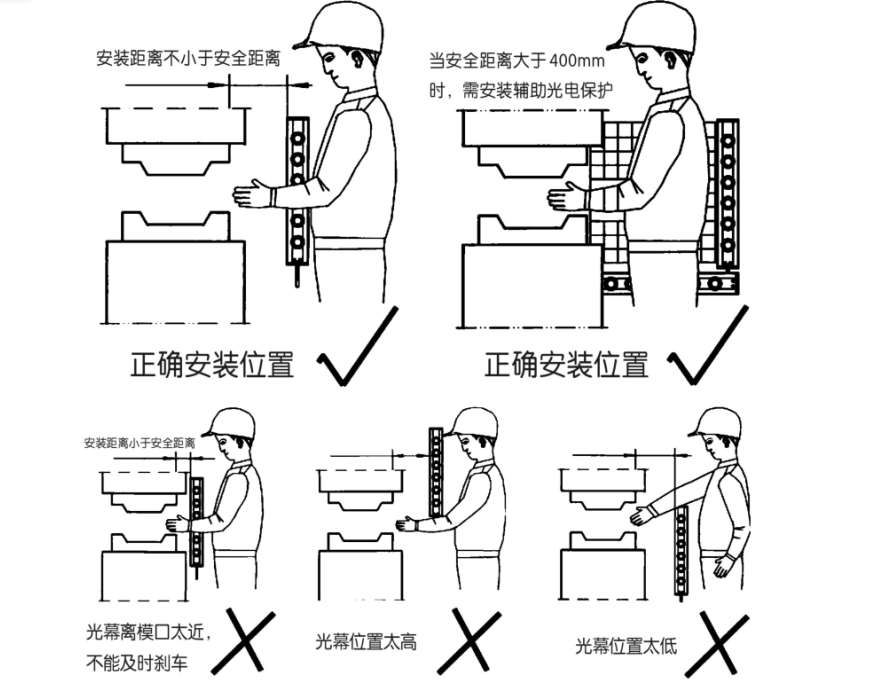

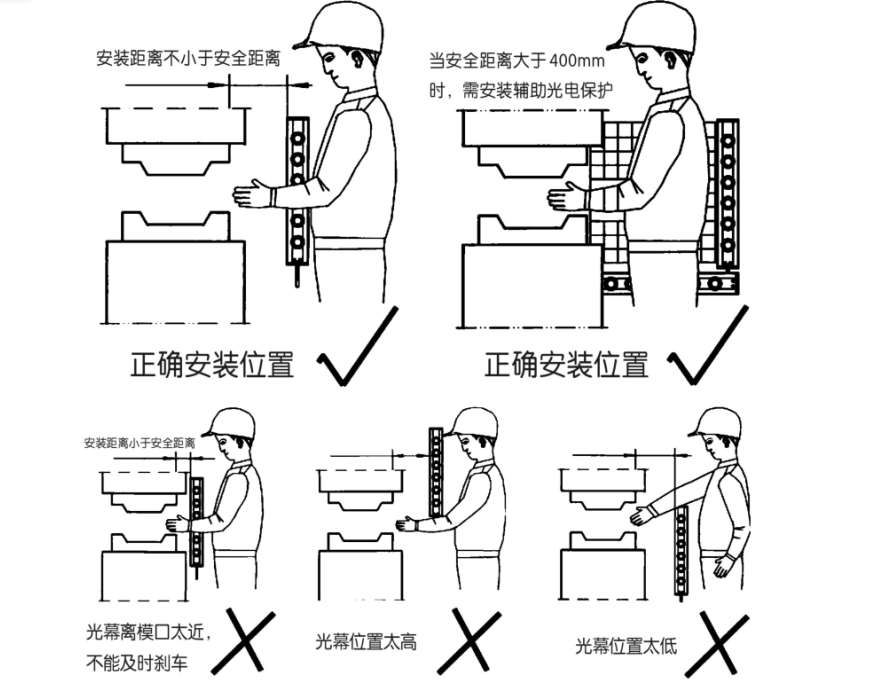

Safety light curtain installation instructions

Note: The installation position refers to the position of the safety light curtain relative to the upper and lower die of the machine. That is, under the premise of ensuring the safety distance, the last light of the safety light curtain shall not be higher than the lower edge of the lower die, and the upper beam shall not be allowed. Below the upper edge of the upper die. This involves the safety light curtain protection height

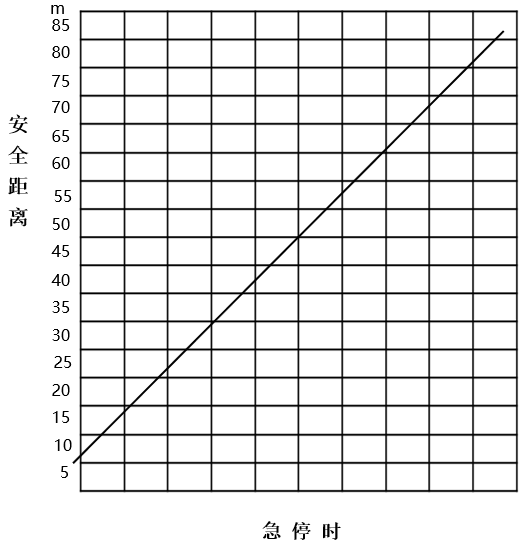

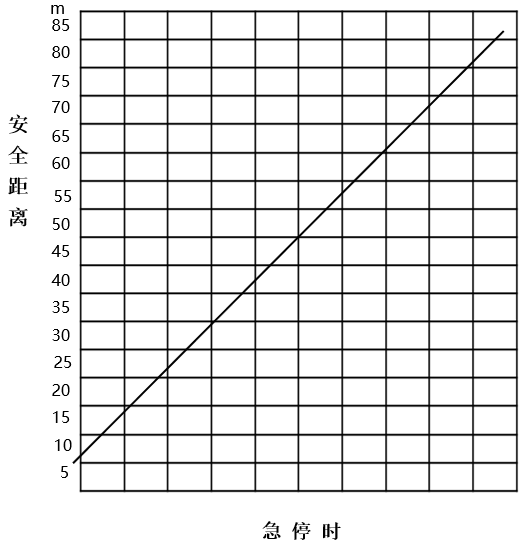

Calculation of safety distance

Calculation of safety distance

In order to ensure the operator's personal safety, the installation position of the safety light curtain must meet the requirements of the safety distance. Otherwise, there is still the possibility of an accident.

■ Safety distance refers to the minimum distance between the light curtain and the cutting edge of the die. The calculation method should be calculated according to the formula of the brake method of the press, or refer to the following table.

■ For presses where the slider can be braked at any position of the stroke, the safety distance:

Ds=1.6(T1+T2)

Where: Ds - safety distance, in meters (m)

1.6 - Stretching speed of the hand, in meters per second (m/s)

T1 - response time of safety light curtain, 0.02 seconds (s)

T2——The braking time of the equipment, that is, the time from the start of braking to the stop of the slider, in seconds (s), measured from the actual braking condition

■ For presses where the slider cannot be braked at any position of the stroke, the safety distance:

Ds=1.6Ts

Where: Ds - safety distance, in meters (m)

1.6 - Stretching speed of the hand, in meters per second (m/s)

Ts - the time from when the person leaves the light curtain (that is, the slider is allowed to start) until the device slider reaches the bottom dead center, that is, the down travel time of the slider, in seconds (s), can be calculated according to the following formula or actually measured:

Ts=(1/2+1/N)T

Where: N - the number of engagement slots of the clutch

Tn - the time the crankshaft makes one revolution, in seconds (s)

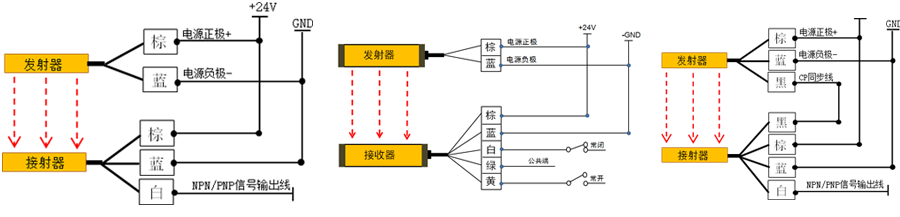

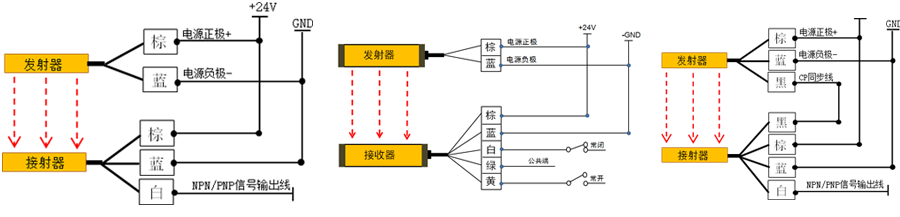

Wiring

Optical synchronization wiring Line synchronous wiring Relay output wiring

Interpretation of indicator status

|

Output form

|

Light curtain state

|

Receiver indicator

|

Output transistor state

|

|

NPNType

|

Pass light

|

Bright green light

|

ON

|

0.3WOutput level≤1V

|

|

Shading

|

Bright red light

|

OFF

|

OPENLeakage current≤2mA

|

|

malfunction

|

Flashing red light

|

OFF

|

OPENLeakage current≤2mA

|

|

PNPType

|

Pass light

|

Bright green light

|

ON

|

0.3W Output level≤1V

|

|

Shading

|

Bright red light

|

OFF

|

OPEN,DO0V Ground resistance10K

|

|

malfunction

|

Flashing red light

|

OFF

|

OPEN,DO0V Ground resistance10K

|

Technical Parameters

|

Product picture

|

|

|

Light curtain type

|

SZF

|

|

Section size

|

18*35 mm

|

|

Enclosure rating

|

IP65

|

|

Supply voltage

|

DC12V-36V±10%

|

|

Response time

|

≤10ms

|

|

Signal output

|

NPN/PNP/Relay

|

|

Synchronization type

|

Optical synchronization / line synchronization

|

|

Number of beams

|

4-500bundle

|

|

Optical axis spacing

|

10mm/15mm/20mm/30mm/40mm/60mm

|

|

Protection height

|

60-2000mm

|

|

Protection distance

|

0.1-3 m

|

|

Light curtain form

|

Opposite type

|

|

Anti-interference ability

|

10000Lux

|

|

Shape material

|

Aluminum alloy

|

|

Circuit protection

|

Reverse protection / output short circuit protection

|

|

Power consumption

|

3-8W

|

|

Operating temperature

|

-15℃--65℃

|

|

Ambient temperature

|

20C,RH≤85%

|

|

Dielectric strength

|

DC30V.5A

|

|

Insulation resistance

|

>100 MΩ

|

|

certified product

|

CE ROHS

|

粵公網(wǎng)安備 44190002004217號 Technical Support:Boryin

粵公網(wǎng)安備 44190002004217號 Technical Support:Boryin